Olemme Tampereella Alihankintamessuilla 24.9.-26.9.2019 osastolla C740

Nurmilo Oy

Nurmilo Oy is a family business founded in 1948, specializing in tailored modern tool manufacturing. The customer can count on our expertise in designing and modelling 3D components as well as machining even more challenging materials, such as Inconel.

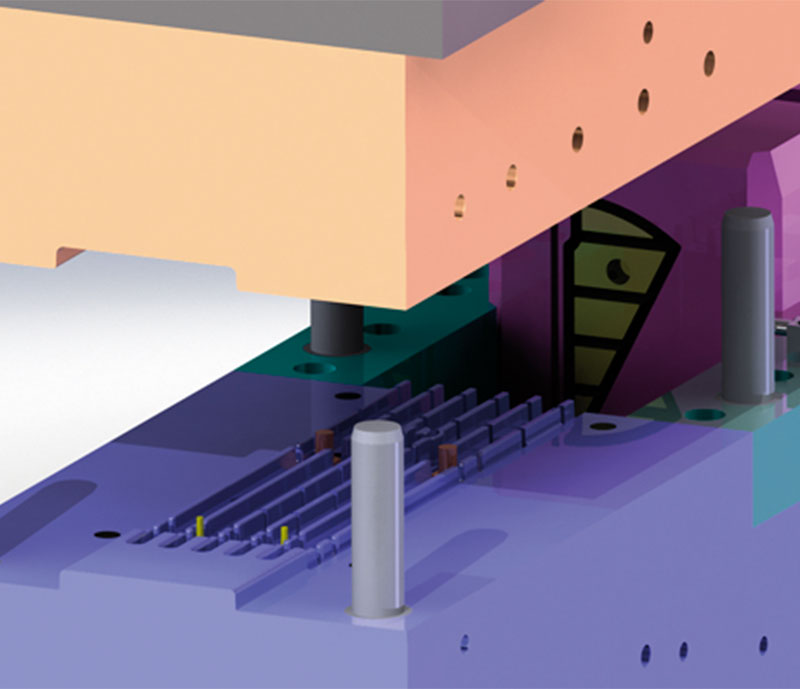

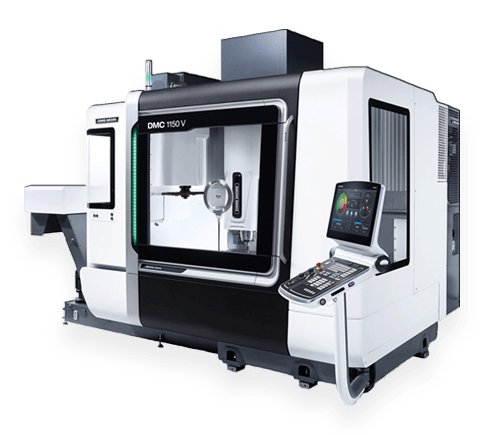

We manufacture molds and tools efficiently with extreme precision using the most advanced technology in the industry. For instance, our modern machinery includes two machines with 5-axis ability and with the hyperMILL® software, we are capable of offering all strategies for 3D and 5-axis milling.

The knowledge and experience gained during the past decades has allowed our product manufacturing processes to develop constantly. Our staff full of professionals are dedicated to make the most of each partnership and offer premium quality products and service for our customers. In addition, Nurmilo Oy utilizes subcontracting relationships in the manufacturing of more specific tools and other larger entities. We subcontract individual pieces, prototypes, small series and machining of 3D prints according to the customer’s needs.

“Our expertise in 3D modeling combined with our modern machinery and experienced staff guarantee the finest result and our competence as a partner. Delivery reliability, reactivity and product precision are the most important qualities of our company.”

_________________

- Panu Nurmilo, CEO

Watch our company video

In addition to tool manufacturing, we have long experience in injection molding of technical plastics. The high quality range of injection molding machines covers clamping force from 25 to 250 tons.

Products

During the mold manufacturing process, our focus is especially on the design of the product as well as its surface and the final result. Our 3D designing and CAM expertise make producing molds with challenging design and material possible.

The AgieCharmilles Fi440 SLP wire-cutting machine that we use allows manufacturing even larger components. The machine is equipped with the Peps WireCAM software.

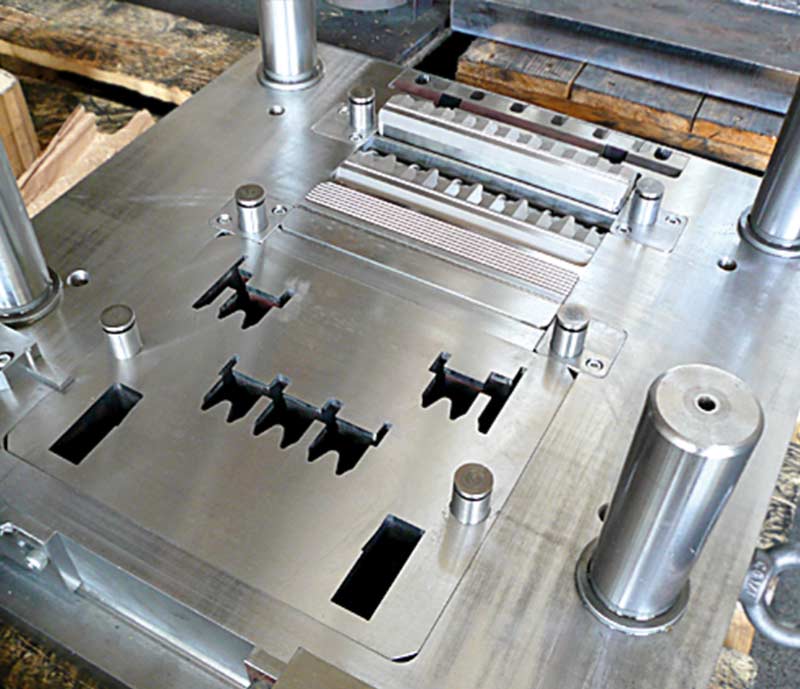

Our extensive knowledge of milling hardened steel is an important prerequisite for producing precise forging tools efficiently.

We subcontract individual pieces, prototypes and small series. The qualified staff and modern machinery guarantee the quality of machined parts.

Our diverse experience in producing sheet metal cutting tools ensure the precision needed in the manufacturing process.

We manufacture plastic parts from technical plastic materials according to the customer´s needs.

Luvata Pori Oy

Our expertise in 5-axis milling and wire-threading has been in a crucial role in producing copper shaping tools and machine parts for Luvata.

Macring Oy

The modern and efficient technology that we use guarantee the competitiveness of Finnish manufacturing in the production of complex deep drawing tools and cutting tools for Macring.

Fiskars Finland Oy Ab

Our company has manufactured tools for Fiskars for more than 30 years. The manufactured tools have been used, for example, in the production of axes, rakes and shovels. Our plastic molds ensure the precise manufacturing of first-class Finnish quality products.